The process of reverse engineering entails obtaining three-dimensional positional data from a point cloud. There are a variety of methods for acquiring useful dimensions information about Reverse Engineering Auto Parts, but the use of precise 3D measurement equipment is essential. The quality and divergence of the Reverse Engineered model in China when compared to the original will be influenced by the precision of the data obtained.

Models And Items Can Be Produced In A Timely And Cost-Effective Manner:

When the objects to be reverse engineered represent a considerable financial investment or will be duplicated in huge quantities, the reverse engineering process is highly cost-effective. Another benefit of reverse engineering is that it shortens the product development cycle.

Manufacturers always attempt to reduce lead times when bringing new Reverse Engineering Auto Parts to market in a highly competitive global market. A 3D model can be swiftly captured in digital form and remodeled if necessary, or exported for a variety of manufacturing methods, including Additive Manufacturing, Vacuum Casting, and CNC machining, using reverse engineering.

What Is The Best Way To Get Data For Reverse Engineering?

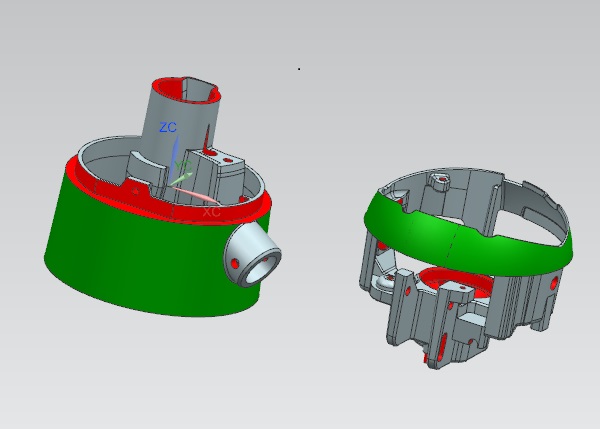

The initial step in developing parametric or free-form surfaces is to represent the geometry of the part in terms of surface points. Using native measuring tools or dedicated reverse engineering software, a highly precise and dense polygon mesh is produced from the point cloud.

The added benefit of a photogrammetry system is that the data gathered for larger items, such as full aircraft or boats, is much more certain. Photogrammetry is a different metrology technology that uses several digital photographs and a certified DSLR camera to capture reference points.

Process of Reverse Engineering:

Different sorts of surfaces can be developed depending on the downstream application for the CAD model. This could include creating a completely parametric CAD model that can be quickly updated, which is likely to be required when redesigning or optimizing a product. When compared to situations when the part will be remanufactured or analyzed and a clean representation could be used.

What Is Reverse Engineering Used for:

Issues with the Original Equipment Manufacturer (OEM) - If the Reverse Engineering Auto Parts are no longer in business or have lost design measurements, Reverse Engineering can provide the necessary product information to keep the object manufactured.

Part Testing, Design Development, & Analysis – Reverse engineering in China allows a 3D product to be swiftly captured in digital form and remodeled or analyzed to improve design iterations.